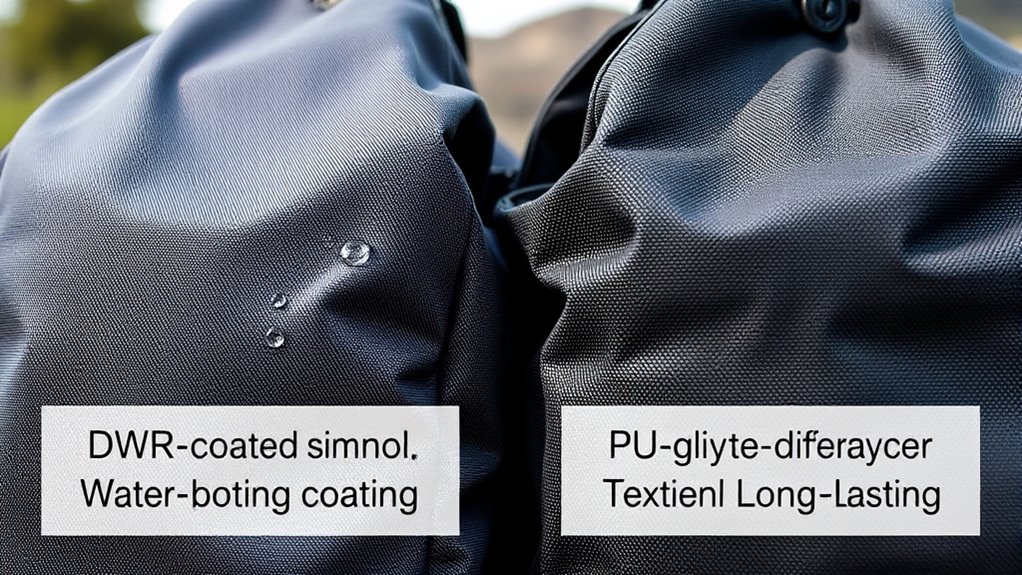

Waterproof coatings like DWR cause water to bead up on nylon bags by increasing surface tension, making droplets roll off easily, while PU forms a flexible barrier directly on the fabric, sealing the fibers. DWR is lighter and less durable but easier to maintain, whereas PU offers longer-lasting waterproofing and better abrasion resistance. If you’re curious about how these coatings impact breathability, longevity, and sustainability, there’s more to explore below.

Key Takeaways

- DWR coatings cause water to bead on fabric surfaces, enhancing water resistance without fully sealing the material.

- PU coatings form a continuous, durable waterproof layer directly on nylon, offering stronger, long-lasting water protection.

- DWR treatments are lightweight and breathable but degrade faster, requiring reapplication; PU coatings provide superior durability.

- Environmental factors like UV exposure and abrasion impact DWR longevity more than PU coatings, which offer better chemical resistance.

- DWR is suitable for lightweight, breathable applications, while PU is ideal for heavy-duty, long-term waterproofing needs.

How DWR Coatings Repel Water Through Surface Tension

Water-repellent Durable Water Repellent (DWR) coatings work by leveraging surface tension to keep water from soaking into fabrics. When water hits a coated surface, surface tension causes the droplets to bead up rather than spread out. This prevents water from penetrating the fabric fibers, maintaining water repellency. The coating creates a hydrophobic barrier on the fabric’s surface, making it difficult for water molecules to pass through. As a result, water remains on the surface in droplets, rather than soaking in and causing wetness or damage. Your fabric stays dry and breathable longer because the DWR coating ensures water stays on the outside, thanks to surface tension. This simple yet effective mechanism is key to the water-repelling properties of DWR-treated fabrics. Understanding the surface tension properties involved helps explain how the coating maintains its water-resistant qualities over time. Additionally, the durability of the coating determines how long these water-repelling features last under various conditions, and the coating’s integrity plays a crucial role in sustaining its effectiveness. Proper maintenance of the coating can also prolong its performance and lifespan, ensuring continued protection against moisture.

The Composition and Application of Polyurethane Coatings

Polyurethane coatings are composed primarily of polymer resins that form a flexible, durable film on fabric surfaces. The polyurethane formulation determines the coating’s flexibility, waterproofness, and ease of application. Proper coating adhesion is essential for durability, ensuring the layer bonds well to nylon bags without peeling or cracking. Applying polyurethane involves evenly spreading the liquid resin, then curing it through heat or moisture, creating a seamless barrier. To visualize, consider this table:

| Aspect | Description |

|---|---|

| Polyurethane formulation | Mix of polyols and isocyanates tailored for flexibility and adhesion |

| Application method | Spray, brush, or roller for uniform coverage |

| Coating adhesion | Critical for waterproof performance and longevity |

Understanding these components helps you select the right polyurethane coating for your needs, especially considering the importance of correct application techniques. Additionally, proper coating curing ensures maximum durability and waterproof effectiveness. Recognizing the significance of coating adhesion can greatly influence the longevity of the waterproof layer.

Durability and Longevity of DWR Versus PU Layers

You’ll want to contemplate how well DWR and PU layers resist wear and tear over time, especially with frequent use. Environmental factors like rain, sun, and temperature fluctuations can also affect their durability and lifespan. Understanding these elements helps you choose the coating that best suits your needs for long-lasting waterproof protection. Additionally, the specific architectural features of the layers can influence how well they withstand environmental stressors over time. The material composition of each coating plays a crucial role in its overall resilience and ability to maintain waterproof qualities under various conditions. Moreover, ongoing research into innovative materials continues to improve the durability and effectiveness of these protective layers.

Wear and Tear Resistance

When considering the durability of waterproof coatings, it’s important to compare the wear and tear resistance of durable water repellent (DWR) layers and polyurethane (PU) coatings. DWR treatments generally have good abrasion resistance, making them effective against surface wear, but they can degrade faster without proper care. Regular maintenance is essential to preserve DWR effectiveness over time. The effectiveness of DWR coatings can diminish when exposed to repeated washing or harsh weather conditions, emphasizing the importance of care and reapplication to maintain performance. PU coatings usually offer superior abrasion resistance, standing up better to repeated friction and handling. Additionally, UV stability plays a role; PU coatings tend to resist UV damage longer, maintaining their protective qualities over time. DWR layers may lose effectiveness when exposed to prolonged sunlight, leading to reduced water repellency. Overall, for wear and tear resistance, PU coatings typically provide a more durable, long-lasting barrier against physical and environmental stressors. Studies also show that coating formulations significantly influence the longevity and performance of these protective layers. Proper application techniques and surface preparation can further enhance the durability of both types of coatings.

Environmental Effects on Coatings

Environmental factors substantially influence the durability and longevity of waterproof coatings, affecting their protective performance over time. Sun exposure, temperature fluctuations, and moisture can degrade coatings, reducing their effectiveness. DWR treatments often have lower chemical resistance, making them more vulnerable to harsh substances like oils or solvents, which can diminish water repellency. In addition, UV radiation can accelerate the breakdown of DWR coatings, leading to faster loss of water repellency UV stability. Environmental exposure can also contribute to coating aging, which affects the overall lifespan of the protective layer. In contrast, PU coatings typically offer better chemical resistance, prolonging their lifespan in challenging environments. However, consider biodegradability; DWR treatments are usually less biodegradable, raising environmental concerns. PU layers, while more durable, may persist longer in ecosystems if improperly disposed of. Additionally, coating durability is affected by the level of environmental exposure, impacting how well your nylon bag withstands daily wear and environmental stressors over time. Environmental exposure can also influence the chemical resistance of coatings, which is crucial for maintaining water repellency in diverse conditions. A comprehensive understanding of environmental impact can help in selecting the most suitable coating for specific needs and environments. Your choice depends on balancing environmental impact with coating longevity, as both factors can influence how well your nylon bag withstands daily wear and environmental stressors over time.

Breathability and Comfort: How Coatings Affect Airflow

While waterproof coatings protect surfaces from water intrusion, they can also impact breathability and comfort by restricting airflow. This limits your ability to vent excess heat and moisture, making your gear less comfortable during active use. A coating’s breathability influences ventilation benefits and moisture management, helping sweat escape and preventing dampness inside your bag. To visualize this, consider the following:

| Coating Type | Effect on Airflow | Moisture Management | Ventilation Benefits |

|---|---|---|---|

| DWR | Slight restriction | Moderate | Good |

| PU | Significant restriction | Limited | Reduced |

Understanding coating permeability can help you select the optimal waterproofing solution for your nylon bags, ensuring a balance between protection and comfort. Additionally, understanding AI security developments can help safeguard your gear and data from emerging digital threats. Being aware of performance impacts helps optimize your gear’s functionality and ensures that waterproofing doesn’t compromise comfort during vigorous activity. Recognizing material breathability is essential for choosing coatings that offer both durability and ventilation. For example, advancements in coating technology have led to new formulations that improve breathability without sacrificing waterproofing quality. Choosing the right coating balances waterproofing with airflow, ensuring comfort and dryness during your adventures.

Environmental Impact and Sustainability of Waterproof Treatments

When choosing waterproof coatings, you should consider their environmental impact and how sustainable they are over time. Eco-friendly materials can reduce harm to ecosystems, but you need to weigh their long-term effects as well. Making informed decisions helps protect the environment while maintaining effective waterproofing.

Eco-Friendly Material Choices

Choosing eco-friendly materials for waterproof coatings can substantially reduce their environmental footprint and promote sustainability. Biodegradable alternatives, such as plant-based oils and waxes, offer natural waterproofing without harmful chemicals. These materials break down more easily in the environment, minimizing pollution and long-term waste. Natural waterproofing methods, like beeswax or lanolin, have been used for centuries and are renewable resources that avoid synthetic toxins. By opting for these options, you help lower the reliance on petroleum-based products and reduce the release of volatile organic compounds (VOCs). Eco-friendly waterproof coatings not only protect your gear but also support environmentally responsible practices. Making conscious material choices guarantees your nylon bags stay functional while aligning with sustainability goals.

Long-Term Environmental Effects

The long-term environmental effects of waterproof coatings depend largely on the materials and methods used in their formulation. Some treatments, like certain durable water repellents (DWR), can lead to chemical leaching over time, releasing substances into soil and water. This chemical leaching can harm aquatic life and disrupt ecosystems. Additionally, waterproof coatings may impact wildlife, especially when animals come into contact with treated fabrics or ingest contaminated water. Polyurethane (PU) coatings, for example, can degrade into microplastics, which pose long-term threats to wildlife. Choosing eco-friendly treatments with minimal chemical leaching reduces these risks. Ultimately, understanding the environmental footprint of waterproof coatings helps you make informed decisions that support sustainability and protect ecosystems for the future.

Maintenance, Repair, and Reapplication of Coatings

Regular maintenance and timely repairs are essential to guarantee your waterproof coatings continue to perform effectively over time. If you notice coating failure, you may need coating removal to strip old or damaged layers before reapplying. This step ensures the new coating adheres properly and restores water resistance. Keep an eye out for color fading, which can indicate the coating’s effectiveness is diminishing. When reapplying, follow manufacturer instructions carefully to ensure even coverage and peak performance. Proper cleaning before reapplication helps remove dirt and oils that can compromise adhesion. For minor damages, spot repairs with waterproof sprays or touch-up treatments can extend the life of your coating. Regular upkeep preserves your nylon bag’s waterproof integrity and prolongs its lifespan.

Performance in Different Weather Conditions and Usage Scenarios

Waterproof coatings must perform reliably across a variety of weather conditions and usage scenarios, as exposure to different elements can challenge their effectiveness. UV resistance is vital, especially when your nylon bag faces prolonged sunlight, preventing breakdown and maintaining waterproof properties. Chemical compatibility also matters, as contact with oils, detergents, or pollutants can weaken certain coatings, reducing their durability. For instance, some DWR finishes may degrade faster with chemical exposure, while PU coatings typically offer better chemical resistance. In diverse conditions such as heavy rain, snow, or high humidity, your coating’s ability to resist UV damage and chemical interactions directly impacts its performance. Selecting a coating with proven UV resistance and chemical compatibility guarantees your nylon bag stays reliably waterproof, regardless of weather or usage intensity.

Cost Considerations and Value for Different Types of Users

When choosing a waterproof coating, balancing cost with performance is essential, especially since different users have varying priorities and budgets. Conducting a cost analysis helps you determine which option offers the best value for your needs. For casual users or those with limited budgets, DWR coatings often provide a cost-effective solution, offering adequate water resistance without breaking the bank. On the other hand, professionals or outdoor enthusiasts who require durability and long-term performance might find PU coatings more suitable, despite their higher initial cost. Considering user suitability ensures you select a coating that aligns with your usage frequency, environmental conditions, and budget constraints. Ultimately, understanding the cost implications helps you make an informed decision that maximizes both performance and value.

Advances in Waterproof Coating Technologies and Future Trends

Recent advancements in waterproof coating technologies are revolutionizing how you protect surfaces from water intrusion. Nanotechnology innovations are enabling the development of ultra-thin, highly effective coatings that provide superior water resistance without adding weight or bulk. These coatings can be engineered at the molecular level, offering enhanced durability and breathability. Additionally, the future leans toward biodegradable coatings, which deliver waterproofing benefits while minimizing environmental impact. Researchers are exploring eco-friendly materials that break down naturally, reducing pollution and waste. As these technologies mature, expect more sustainable, high-performance options that meet both your waterproofing needs and environmental concerns. These trends point toward smarter, greener solutions that blend innovation with responsibility, shaping the next generation of waterproof coatings.

Frequently Asked Questions

How Do DWR and PU Coatings Affect the Flexibility of Nylon Bags?

You might notice that DWR coatings generally keep nylon bags more flexible because they have better coating elasticity, which minimizes fabric stiffness. PU coatings, however, tend to make the fabric stiffer over time due to their less elastic nature. So, if you want a bag that stays more pliable and comfortable to carry, DWR coating is usually your better choice, as it preserves the fabric’s flexibility longer.

Can DWR or PU Coatings Be Hazardous to Health During Manufacturing?

Ever wonder if your nylon bag’s waterproof coating could pose health risks? During manufacturing, both DWR and PU coatings can release hazardous chemicals, exposing workers to potential health risks and manufacturing hazards. These chemicals, like PFCs in DWR or solvents in PU, may cause respiratory issues or skin irritation. It’s essential for manufacturers to follow strict safety protocols to minimize these risks and protect everyone involved in the production process.

Are There Differences in Repairability Between Dwr-Treated and Pu-Coated Fabrics?

You’ll find that repairability varies between DWR-treated and PU-coated fabrics. DWR coatings tend to be more durable, so minor repairs like reapplying a DWR spray or patching small areas often work well. PU coatings, however, can crack or peel more easily, making repairs trickier. To restore waterproofness, focus on methods like seam sealing or using compatible repair kits, but remember that coating durability influences how effective these repair techniques will be over time.

How Do Coatings Impact the Recyclability of Nylon Bags?

You’re facing the formidable recycling challenges of waterproof coatings, which considerably complicate nylon bag recycling. Coatings like DWR and PU can inhibit material separation, making recycling nearly impossible. This impacts eco-friendly alternatives, as coated fabrics often end up in landfills. To truly protect our planet, seek bags with removable or biodegradable coatings, ensuring sustainability without sacrificing waterproof performance—because saving the environment shouldn’t be an uphill battle.

What Are the Environmental Trade-Offs Between DWR and PU Coatings?

You should consider the environmental trade-offs between DWR and PU coatings. DWR uses eco-friendly alternatives like fluorine-free treatments, which support long-term sustainability and reduce pollution. PU coatings, while durable, often involve chemicals that are less eco-friendly and harder to recycle. Choosing environmentally conscious options helps minimize impacts on ecosystems and promotes sustainable practices, ensuring your nylon bags remain eco-friendly and aligned with long-term sustainability goals.

Conclusion

Ultimately, whether you choose DWR or PU coatings depends on your needs and values—each reflects a different approach to protection and sustainability. As technology advances, you’ll find smarter, more eco-friendly options emerging, reminding you that innovation often follows the simplest moments of necessity. So, in your quest for durability and comfort, remember that even the tiniest coating can make a big difference—showing that sometimes, the smallest change leads to the greatest impact.